- Horizontal table surface grinding machine (High Precision)

- Editor:xghlDate:2017-01-05 10:42 click:

- 產(chǎn)品詳情

- 產(chǎn)品參數(shù)

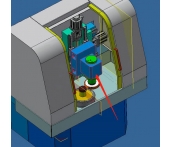

CNC Horizontal table surface grinding machine SSKMG7380 (high precision)

Equipment principle and construction:

SSKMG7380 with grinding head in the carriage for reciprocating carriage in the column rails for vertical movement of the form. Bed, pillars and other castings all use secondary tempering stress relief processing material is good, high strength, to ensure the stability of the equipment.

Advantages:

Independent research and development grinder feed NC control system with easy parameter settings. Operates by keys, automatic knife, automatically calculates the grinding edge, grinding is more uniform, reduces the amount of deformation, processing more accurate and efficient production. The equipment uses the speed (CBN) the grinding wheel to process both ends while enhancing the end surface smoothness. Uniform size, especially the grinding of the step surface. The workbench is equipped with automatic charge and a demagnetization device, with magnetic adjustment, loss of magnet protection and other functions. Equipment selection Hydro-static grinding head, using imported rails. Operating system, independent research and development, is now the most convenient and most humane operation. A strong after-sale protection.

Characteristics:

1. The adaptability of processed products;

2. high precision,

3. After processing up to Ra 0.4 μm, the work piece thickness of the gap remains at 0.003mm within the roughness surface.

4. the operator labor intensity is low, one person control multiple machines, reduce labor costs;

5. High production efficiency and good economic efficiency

6. Simple grinder maintainance

7. Easy to produce Management modernization.

8. For high-precision work piece processing.

Equipment principle and construction:

SSKMG7380 with grinding head in the carriage for reciprocating carriage in the column rails for vertical movement of the form. Bed, pillars and other castings all use secondary tempering stress relief processing material is good, high strength, to ensure the stability of the equipment.

Advantages:

Independent research and development grinder feed NC control system with easy parameter settings. Operates by keys, automatic knife, automatically calculates the grinding edge, grinding is more uniform, reduces the amount of deformation, processing more accurate and efficient production. The equipment uses the speed (CBN) the grinding wheel to process both ends while enhancing the end surface smoothness. Uniform size, especially the grinding of the step surface. The workbench is equipped with automatic charge and a demagnetization device, with magnetic adjustment, loss of magnet protection and other functions. Equipment selection Hydro-static grinding head, using imported rails. Operating system, independent research and development, is now the most convenient and most humane operation. A strong after-sale protection.

Characteristics:

1. The adaptability of processed products;

2. high precision,

3. After processing up to Ra 0.4 μm, the work piece thickness of the gap remains at 0.003mm within the roughness surface.

4. the operator labor intensity is low, one person control multiple machines, reduce labor costs;

5. High production efficiency and good economic efficiency

6. Simple grinder maintainance

7. Easy to produce Management modernization.

8. For high-precision work piece processing.

- next: 7333 CNC Horizontal Grinding Machine with Round Surface

- pre: end...